Company News

Your current position: Home >> News Information >> Company News

Analysis of the difference between CO2 laser marking machine glass tube and RF

Source: Shenzhen Connaught Laser Technology Co., LtdPopularity: 2055Time: 2016-08-25【SML】

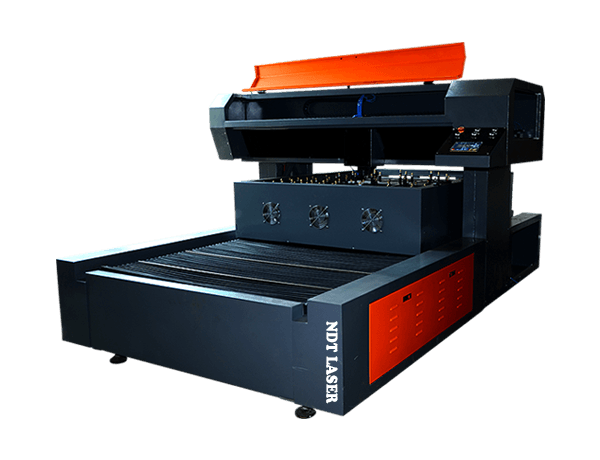

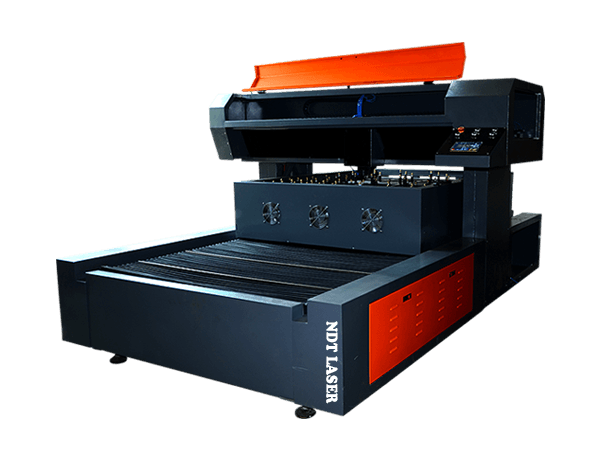

Laser marking machine is a laser beam in a variety of material surface marked with a permanent marker. Marking effect is exposed deep material by evaporation of surface material, thereby carve beautiful designs, trademarks and text, laser marking machine is mainly divided, CO2 laser marking machine, laser marking machine, fiber laser marking machine and YAG laser marking machine, laser marking machine is currently mainly used in some of the requirements for more sophisticated, higher accuracy of the occasion. Used in electronic components, integrated circuits (IC), electrical appliances, mobile communications, hardware, tools, accessories, precision instruments, eyeglasses and clocks, jewelry, auto parts, plastic buttons, construction material, PVC pipe.

CO2 laser marking machine commonly used laser tube glass tube and RF tube of the points, the difference between the two is:

1, the laser tube: CO2 RF laser marking machine adopts imported laser tube; and the use of domestic glass laser tube.

2 life: CO2 RF laser marking machine life of up to 45,000 hours, and can be use for six years, inflatable reusable without replacement; and glass marking only about 2500 hours, usually six months to replace a supporting glass, can not be reused, to be replaced.

3, cooling method: CO2 RF laser marking machine adopts air-cooled, can ensure long-term trouble-free and stable operation; CO2 glass laser marking machine adopts water-cooled, the light may not work long hours or high water temperature or intermittent light continuous work on product quality greater impact.

4, the spot size (beam): CO2 RF laser marking machine is 0.07mm spot fine, three times more than the fine glass tube, high precision, small thermal diffusion area, can engraving / cutting very fine work; CO2 laser glass marking the spot is 0. 25mm thick, the accuracy is poor, unstable light (light intensity is uneven, sometimes not light), heat diffusion area, trimming melted, blackened clear, relatively poor precision carving.

5. Stability: RF tube is fully sealed metal tube, using a 30-volt low voltage power supply, which is directly avoids the use of high voltage power supply brings some disadvantages; because of domestic glass tube laser cutting machine is 10000 volts or even higher high voltage power supply, in addition to external instability there is a certain risk, long working hours so that the power is liable to deteriorate, and the control system has a lot of interference, such as improper operation easy to burn out the motherboard, more vulnerable to voltage Effect damage its normal function.

6, price: RF tube many times more expensive than the price of a glass tube, and for some products such as leather processing, only the glass tube can be completely competent. Therefore, depending on their needs marking machine is the last word.

CO2 laser marking machine commonly used laser tube glass tube and RF tube of the points, the difference between the two is:

1, the laser tube: CO2 RF laser marking machine adopts imported laser tube; and the use of domestic glass laser tube.

2 life: CO2 RF laser marking machine life of up to 45,000 hours, and can be use for six years, inflatable reusable without replacement; and glass marking only about 2500 hours, usually six months to replace a supporting glass, can not be reused, to be replaced.

3, cooling method: CO2 RF laser marking machine adopts air-cooled, can ensure long-term trouble-free and stable operation; CO2 glass laser marking machine adopts water-cooled, the light may not work long hours or high water temperature or intermittent light continuous work on product quality greater impact.

4, the spot size (beam): CO2 RF laser marking machine is 0.07mm spot fine, three times more than the fine glass tube, high precision, small thermal diffusion area, can engraving / cutting very fine work; CO2 laser glass marking the spot is 0. 25mm thick, the accuracy is poor, unstable light (light intensity is uneven, sometimes not light), heat diffusion area, trimming melted, blackened clear, relatively poor precision carving.

5. Stability: RF tube is fully sealed metal tube, using a 30-volt low voltage power supply, which is directly avoids the use of high voltage power supply brings some disadvantages; because of domestic glass tube laser cutting machine is 10000 volts or even higher high voltage power supply, in addition to external instability there is a certain risk, long working hours so that the power is liable to deteriorate, and the control system has a lot of interference, such as improper operation easy to burn out the motherboard, more vulnerable to voltage Effect damage its normal function.

6, price: RF tube many times more expensive than the price of a glass tube, and for some products such as leather processing, only the glass tube can be completely competent. Therefore, depending on their needs marking machine is the last word.

Prev: None

Next: Laser marking machine which features application which

Related Information

Analysis of the difference between CO2 laser marking machine glass tube and RF

2016-08-25Laser marking machine which features application which

2016-08-25Laser Marking Machine details in some of the industry

2016-08-25CO2 laser marking machine use process

2016-08-25Full analysis: laser burning flowers processing technology in the garment accessories industry

2016-08-25