Company News

Your current position: Home >> News Information >> Company News

Laser Marking Machine details in some of the industry

Source: Shenzhen Connaught Laser Technology Co., LtdPopularity: 1452Time: 2016-08-25【SML】

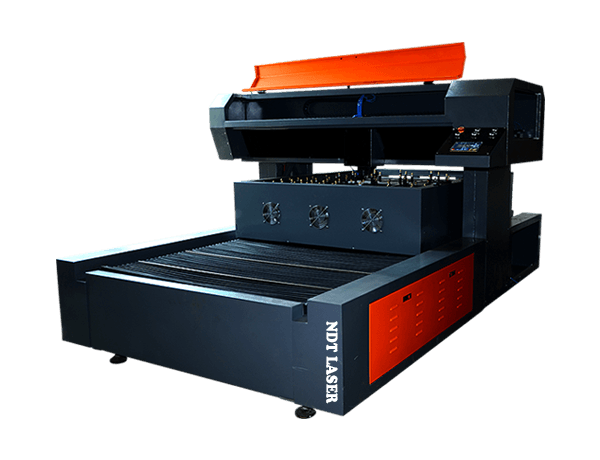

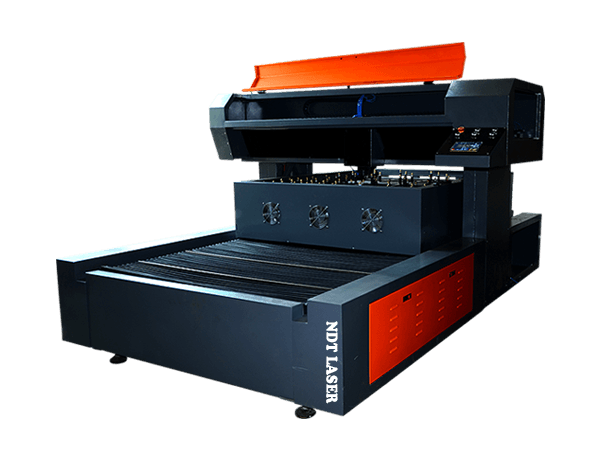

In recent years, with the rapid development of laser marking machine technology applications in different industries is increasingly widespread, superior performance advantages and unique processing characteristics, such that it has a way unmatched by traditional processing features. Although laser marking machine prices compared with the conventional device, or a lot more expensive, but laser marking machine with a permanent marker, efficient, no supplies, high reliability, high stability and many other features, these performance advantages for us now processing provides a lot of convenience. In order to effectively utilize the current application of laser technology, we use laser equipment, because of the different materials, differences in product performance, we need to according to the specific needs of different industries to be adjusted to achieve the best processing results.

In the marking process is now in the food, pharmaceutical and packaging industries, in order to effectively guarantee each product information tags, we need the time markers, using specific transmission speed sensors automatically detect the belt, to adjust the labeling process tag speed, in order to ensure that each product does not leak to fight for the belt speed uneven situation to be accurately labeled to ensure each product. Making leather products marking time, we need to be labeled according to a specific pattern, and sometimes also need to portray hollow, leather for larger areas, we need to do the exact make-up to ensure the integrity of the pattern data. In the labeling process in the electronics industry, the main attention to the precision machining, as well as to ensure the smooth texture of the surface, while some also need to meet the pipeline operations. In general, hardware, bearings, aluminum, sanitary ware faucet marking process, the process when we need to according to the actual needs of specific markers to adjust the depth, but also pay attention to the surface color transformation, for some complex shapes labeling of products, we also need to set up different parameters in the software. Now in jewelry process, we need to manufacture very precise, but also need to have an accurate positioning of the red dot. Not the industry due to various differences, according to the actual needs of our processing needs, a good grasp of some of the details of processing, so that application of laser technology to achieve our desired processing results.

In the marking process is now in the food, pharmaceutical and packaging industries, in order to effectively guarantee each product information tags, we need the time markers, using specific transmission speed sensors automatically detect the belt, to adjust the labeling process tag speed, in order to ensure that each product does not leak to fight for the belt speed uneven situation to be accurately labeled to ensure each product. Making leather products marking time, we need to be labeled according to a specific pattern, and sometimes also need to portray hollow, leather for larger areas, we need to do the exact make-up to ensure the integrity of the pattern data. In the labeling process in the electronics industry, the main attention to the precision machining, as well as to ensure the smooth texture of the surface, while some also need to meet the pipeline operations. In general, hardware, bearings, aluminum, sanitary ware faucet marking process, the process when we need to according to the actual needs of specific markers to adjust the depth, but also pay attention to the surface color transformation, for some complex shapes labeling of products, we also need to set up different parameters in the software. Now in jewelry process, we need to manufacture very precise, but also need to have an accurate positioning of the red dot. Not the industry due to various differences, according to the actual needs of our processing needs, a good grasp of some of the details of processing, so that application of laser technology to achieve our desired processing results.

Related Information

Analysis of the difference between CO2 laser marking machine glass tube and RF

2016-08-25Laser marking machine which features application which

2016-08-25Laser Marking Machine details in some of the industry

2016-08-25CO2 laser marking machine use process

2016-08-25Full analysis: laser burning flowers processing technology in the garment accessories industry

2016-08-25