Industry News

Your current position: Home >> News Information >> Industry News

Laser marking is a non-contact permanent marker

Source: Shenzhen Connaught Laser Technology Co., LtdPopularity: 2160Time: 2016-08-25【SML】

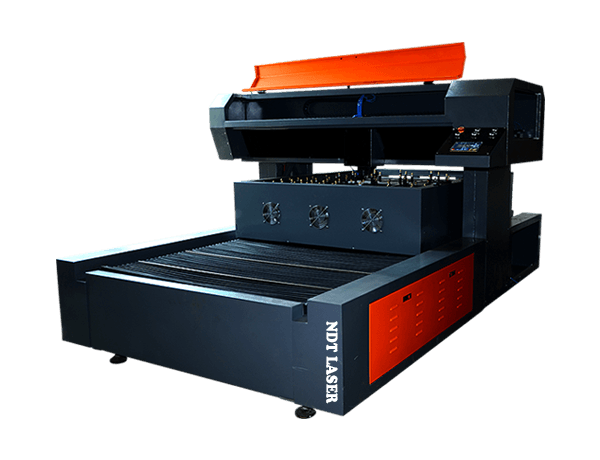

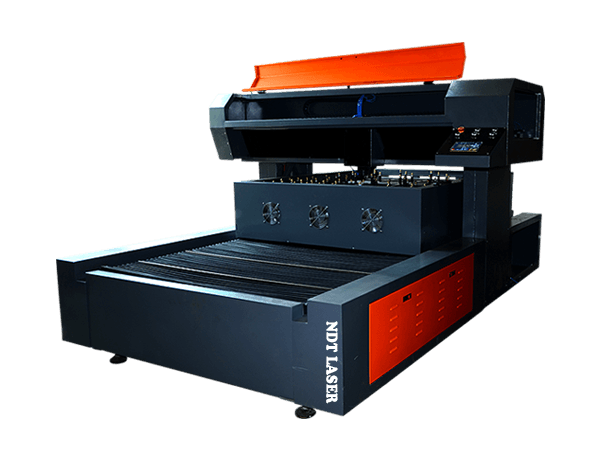

Laser marking is through the use of high energy density of the laser beam on the target role, so that the target surface physical or chemical changes, resulting in visible way mark pattern produced by laser action on the surface of the workpiece firmly permanent marker is its outstanding feature. Laser marking machine, also known as (laser typewriter, laser printer, laser marking machine), laser processing is an important principle, namely the use of laser-beam irradiation treatment of the material surface, the light energy is converted into heat instantly, so that the surface even molten material instantly vaporized to form a tag.

In recent years, laser marking technology more and more applications in the field of printing, laser marking machine can be used include plastic and rubber, metal, silicon wafers and other materials, laser marking machine is easy to operate, as long as understand basic computer knowledge, will be able to operate the laser marking machine; marking in the printing industry, laser marking has the following characteristics:

1. Permanent: The tag will not be because of environmental relations (touch, acidic and basic gases, heat, cold, etc.) and subside.

2. The security: the use of laser marking technology marks carved out and change is not easy to imitate, to some extent, has a strong anti-counterfeiting.

3. Non-contact: Laser marking is a non-mechanical "knife" for processing, after the workpiece does not produce stress at any regular or irregular surface of the print mark, and marking, to ensure accuracy of the original workpiece. The work surface does not produce corrosion, no "tool" wear and tear, no poison, no pollution, is a clean, non-polluting high environmental processing technology.

4. Wide applicability: a laser processing means to do, can be a variety of metals, non-metallic materials (aluminum, copper, iron, wood, etc.) processing.

5. High precision engraving: laser marking machine engraving Patterns fine items, the minimum line width of up to 0.04mm marking a clear, durable, and beautiful. Laser marking can meet print large amounts of data on a tiny plastic parts need to have a stronger market competitiveness.

6. Low operating costs: marking speed and marked molding, low energy consumption, and therefore lower operating costs. Although laser marking machine equipment investment is larger than conventional marking equipment, but operating costs, the use of laser marking confidential much lower. Illustration: ① plastic transistor marking: marking machine working speed of 10 / sec to 5 years if the equipment depreciation calculation, marking fee 0.00048 yuan / month. If you use a printing machine, its overall operating cost of about 0.002 yuan / month, or even higher.

7. The high efficiency: the laser beam under computer control high-speed mobile (speeds of up to 5-7 m / s), can play a variety of characters, symbols and patterns, marking process can be completed within seconds, easy-to-use label design software engraved pattern, change tag content to adapt to modern production of high efficiency, fast-paced requirements.

8. The development of fast: due to a combination of laser technology and computer technology, the user as long as the computer programming to achieve laser printer output, and can change at any time print design, replacing the traditional mold making process fundamentally, in order to shorten product upgrades replacement cycle and flexible production provides a convenient tool.

If equipped with a laser or Q-MOPA10W, 20W pulsed fiber laser laser marking machine, the whole system of marking high precision, fast, stable performance, can be configured to be able to work long hours of work delivery platform (also available in the customer's production line direct mounting on) and equipped with encoders and sensors, so that a continuous dynamic marking production line more quickly and accurately, with traditional laser marking machine photoelectric conversion efficiency with higher contrast, higher stability, the advantages of easier operation and comparison with traditional inkjet printer ink is more environmentally clean pollution-free advantages of low consumption, more lasting mark with security features. With the continuous expansion of modern laser marking applications, the device miniaturization, efficiency and integration requirements of the laser manufacturing also higher.

In recent years, laser marking technology more and more applications in the field of printing, laser marking machine can be used include plastic and rubber, metal, silicon wafers and other materials, laser marking machine is easy to operate, as long as understand basic computer knowledge, will be able to operate the laser marking machine; marking in the printing industry, laser marking has the following characteristics:

1. Permanent: The tag will not be because of environmental relations (touch, acidic and basic gases, heat, cold, etc.) and subside.

2. The security: the use of laser marking technology marks carved out and change is not easy to imitate, to some extent, has a strong anti-counterfeiting.

3. Non-contact: Laser marking is a non-mechanical "knife" for processing, after the workpiece does not produce stress at any regular or irregular surface of the print mark, and marking, to ensure accuracy of the original workpiece. The work surface does not produce corrosion, no "tool" wear and tear, no poison, no pollution, is a clean, non-polluting high environmental processing technology.

4. Wide applicability: a laser processing means to do, can be a variety of metals, non-metallic materials (aluminum, copper, iron, wood, etc.) processing.

5. High precision engraving: laser marking machine engraving Patterns fine items, the minimum line width of up to 0.04mm marking a clear, durable, and beautiful. Laser marking can meet print large amounts of data on a tiny plastic parts need to have a stronger market competitiveness.

6. Low operating costs: marking speed and marked molding, low energy consumption, and therefore lower operating costs. Although laser marking machine equipment investment is larger than conventional marking equipment, but operating costs, the use of laser marking confidential much lower. Illustration: ① plastic transistor marking: marking machine working speed of 10 / sec to 5 years if the equipment depreciation calculation, marking fee 0.00048 yuan / month. If you use a printing machine, its overall operating cost of about 0.002 yuan / month, or even higher.

7. The high efficiency: the laser beam under computer control high-speed mobile (speeds of up to 5-7 m / s), can play a variety of characters, symbols and patterns, marking process can be completed within seconds, easy-to-use label design software engraved pattern, change tag content to adapt to modern production of high efficiency, fast-paced requirements.

8. The development of fast: due to a combination of laser technology and computer technology, the user as long as the computer programming to achieve laser printer output, and can change at any time print design, replacing the traditional mold making process fundamentally, in order to shorten product upgrades replacement cycle and flexible production provides a convenient tool.

If equipped with a laser or Q-MOPA10W, 20W pulsed fiber laser laser marking machine, the whole system of marking high precision, fast, stable performance, can be configured to be able to work long hours of work delivery platform (also available in the customer's production line direct mounting on) and equipped with encoders and sensors, so that a continuous dynamic marking production line more quickly and accurately, with traditional laser marking machine photoelectric conversion efficiency with higher contrast, higher stability, the advantages of easier operation and comparison with traditional inkjet printer ink is more environmentally clean pollution-free advantages of low consumption, more lasting mark with security features. With the continuous expansion of modern laser marking applications, the device miniaturization, efficiency and integration requirements of the laser manufacturing also higher.

Prev: None

Related Information

Laser marking is a non-contact permanent marker

2016-08-25CO2 laser marking machine works

2016-08-25CO2 laser marking machine classification Composition

2016-08-25The domestic apparel industry uses laser technology to process

2016-08-25Laser equipment in areas such as leather clothing more and more popular

2016-08-25